The Department offers world class facilities both for teaching and research. Some specific highlights of the facilities available include the following.

Teaching Facilities

- Computing Facilities

Main Computer Laboratory

The department has a general access computing laboratory where students can access specialist software and standard applications including email and web browsers. It is stocked with 44 Dell workstations running Linux, with remote access to Microsoft Windows Servers that include the Microsoft Office suite.

The available software includes, Advanced Design System (ADS), Mathematica, Matlab, ModelSim, Quartus Prime, Vivado, Netbeans, Eclipse, PyCharm, LibreOffice and much more. A large multifunction printer/scanner/photocopier is also available in the laboratory.

Remote Facilities

The department offers remote connectivity to its computing facilities via Oracle's Secure Global Desktop. This allows students to access Microsoft Windows/Linux services/applications off site, via a standard web browser.

Wireless Access

The department is covered by the Eduroam cross-campus wireless service, providing access for mobile phones and portable devices.

- Undergraduate Teaching Laboratory

The lab has 66 PC's running Windows, with access to the Microsoft Office suite and a wide range of specialised software for the modelling, simulation and layout of electronic circuit designs.

There are 33 dedicated workbenches consisting of an oscilloscope, power supply, 2 channel Arbatry waveform generator, alongside two benchtop multimeters. Students will use this industry standard test equipment to develop their practical knowledge and understanding of electrical and electronic circuits and principles.

The teaching lab also contains a number of specialised pieces of equipment to aid the construction of modern small scale surface mount circuits.

- PDR IR rework station

- Mechatronika pick and place machine

- DDM Novastar 3 zone reflow oven.

- Batch Reflow ovens

- Range of soldering/de-soldering equipment.

To assist students in developing the increased range of prototype products based around mechatronic designs we have a range of 3D printers which allow rapid prototyping of 3D objects to compliment their electronic circuit design.

- Broadband Teaching Laboratory

Experimental and practical skills are an important part of the skill set of any Engineer. The broadband communications lab offers access to state-of-the-art test and measurement equipment as would be found in research and development labs around the world.

The equipment is used as part of the Broadband Communications Laboratory courses as well as being available for undergraduate and postgraduate projects. The lab offers all commonly used test and measurement equipment for RF Circuit and Optical Component and system testing to allow students to become familiar with industry standard measurement procedures as well as to make measurements as part of their projects.

Anritsu Optical Spectrum Analyser Agilent 6GHz Lightwave Component Analyser Anritsu Bertwave Bit Error test set Agilent Infinium 6 Ghz 20Gs/s Oscilloscope Rigol 6GHz Electrical Spectrum Analyser Rhode&Schwarz 6GHz Vector Signal Generator Rhode&Schwarz 13.6GHz Vector Signal Analyser Agilent 3GHz Vector Network Analyser Agilent 2.5Gbit/s optical Transmitter and Receiver Variety of Optical Sources, Modulators and RF components (amplifiers, filters etc.) Erbium Doped Optical Amplifier Fujikura fusion splicer

- Project Laboratory

- The project lab is a dedicated space for use by 3rd and 4th year students to build, assemble and test their circuits. A wide range test equipment is available in the lab along with surface mount soldering stations, microscope, and reflow oven.

There are 26 workstations consisting off;

- Dedicated PC with test and development software.

- Keithly 2231A triple output power supply.

- Pico 3000 series Dual channel 100MHz oscilloscope with 16 digital inputs, and arbitrary waveform generator.

- Rigol DM3058 5 ½ digit digital multimeter.

- Nanotechnology Facilities

The nanotechnology laboratory is a teaching and research facility designed to give MSc students a practical insight into different nanoscale characterisation tools such as atomic force spectroscopy (AFM), scanning tunnelling microscopy (STM), and photospectrometry. These skills are acquired during the 12 week course ‘Experimental Techniques in Nanotechnology’ which is currently offered to students enrolled in the MSc in Nanotechnology. The lab is also available to research students and undergraduate students undertaking projects in this area. In addition there are two three-day intensive workshops for the advanced characterisation of materials CDT which cover the subjects of scanning probe microscopy and optics. All equipment located in the nanotechnology lab is available for undergraduate projects and postgraduate research.

The equipment in the nanotechnology laboratory is being used to research resistive memory (ReRAM), diamond electronics, crystal surfaces, photonics, solar cells, and data recovery. Currently we have 3X Nanosurf Easyscan2 AFMs, 3X Nanosurf Easyscan2 STMs, a Veeco diDimension AFM, a Bruker ICON AFM, a Keithley 4200A semiconductor characterisation system, UV-Vis, FTIR, JEOL JSM IT-100 SEM, a Quorum Au/Pd sputterer, a sonoplot microplotter II, A scanning kelvin probe, a Renishaw InVia Raman spectrometer, and a LifeSpec ps photoluminescence kit.

To visit the nanotechnology laboratory please contact the lab manager Dr. Steve Hudziak by email s.hudziak@ucl.ac.uk.

Research Facilities

- Molecular Beam Epitaxy

Molecular Beam Epitaxy (MBE) is an epitaxy method for the nano-scale compound semiconductor. The epitaxy takes place in the ultra-high vacuum (basic pressure 10-13 bar). Due to the ultra-high vacuum, the epitaxial growth of semiconductors with the highest achievable purity (>99.99999%) and precision growth rate (<0.01 nanometer) can be realised. The compound semiconductor materials are deposited on the top of substrate layer to form optoelectronic and electronic semiconductor epi-structure, such as transistors and lasers, which can be used in fibre-optics, cellular phones, satellites, radar systems, solar cells, and display devices. The samples with complex structures grown by MBE system are further fabricated to produce a range of electronic and optoelectronic devices, including high electron mobility transistor (HEMT), light-emitting source, quantum dot (QD) laser, high-efficiency solar cell, quantum cascade laser (QCL), and etc. Few high performance electronic and optoelectronic devices, such as HEMT and QD laser, need low background doping, in which case the MBE is the appropriate method to grow the epi-structure.

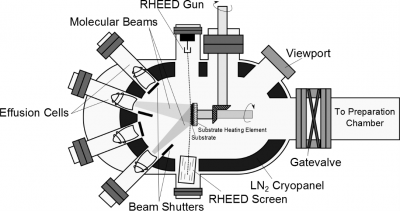

Figure 1: Schematic diagram of the growth chamber for an MBE system.

Within the solid-source MBE system as shown in Figure 1, the atoms or molecules in the form of gas molecule deposit on the substrate to form the growing solid layer with growth rates between 0.001 monolayer/second and 2 monolayer/second (The thickness of 1 monolayer GaAs is about 0.28 nm). Typically, each element is evaporated in a separately controlled beam, so the choice of components and their relative concentrations can be adjusted for any given layer. Each gas beam can be switched rapidly within 0.2 seconds. As a result, each layer with specified precise composition, certain thickness, electrical and optical characteristics can be grown.

Figure 2 : Twin Chamber MBE systems.

The twin chamber MBE system shown in Figure 2 in the UCL EE department was established in 2010. This MBE system provides high-quality III-V and group IV semiconductor material growth which expend the limitation of semiconductor materials in UCL. The twin chamber MBE system consists of one Vecco GEN 930 Group III-V and one Vecco GEN 930 Group IV MBE. Group III-V MBE system has solid source Indium, Gallium, Aluminum, Phosphorus, Arsenic and Antimony materials. It also has the doping cells Silicon and Beryllium. An additional Phosphorus recovery system is needed to eliminate the contamination of residual Phosphorus. As for Group IV MBE system, it has Germanium, Silicon, and Tin sources, with doping cells Boron and Antimony and a Si E-beam source. Now the twin chamber MBE system mainly focused on the researches of low-dimensional structures including quantum wells, nanowires, and quantum dots.

The UCL twin chamber MBE system serves as a vital role in enhancing the reputation in nanotechnology and photonics for UCL and London Centre for Nanotechology. Discover more about the research activities of UCL MBE group . Additionally, it works for EPSRC Future Compound Semiconductor Manufacturing Hub and EPSRC National Epitaxy Facility. It builds up the competitiveness for UCL in optoelectronic and semiconductor science, boosting research in nanotechnology.

- Anechoic Chamber

The EEE Department is fortunate to have an anechoic antenna chamber for measuring the radiation performance of antennas and radio transceivers in order to determine their gain, directionality and other key properties. The instrument operates at a distance in the far-field region. This allows considerable versatility in the measurement of a wide range of antenna types in a small space, and is a facility that is usually only available in industry. Antennas of up to 0.5 m in length and 20 kg in weight may be measured over a 1 to 40 GHz range. A screened room is used in order to reduce interference from external signals, in which 100 dB of suppression, to 40 GHz, is achieved. The room is lined with radiation absorbing material (RAM) to reduce reflections that would otherwise result in pattern measurement errors. It has many applications, such as mobiles, wearable, IoT, medical devices, and radar.

- Converged Networks and Systems Laboratory (CONNET)

The CONNET Lab hosts the UCL Access Point for the Aurora2 Network, operated by the National Dark Fibre Infrastructure Services (NDFIS).

NDFIS is an EPSRC National Research Facility, with the leased fibre provided by JISC, Janet.

The Aurora2 Network comprises some 630 km of single mode optical fibre linking the Universities of Bristol, Cambridge, Southampton and UCL, with connections to other networks through Telehouse.

The Network includes software defined networking features to provide remote reconfigurability and adjustment of network parameters, such as dispersion compensation and gain distribution.

The Network can be used to support the experiments of any institution eligible to receive grant support from EPSRC.

Further details of NDFIS are at www.ndfis.org

- Mechatronics Workshop

The workshop contains a dedicated printed circuit board (PCB) manufacturing facility capable of manufacturing multilayer PCB’s down to 0.1mm track and gap and 0.2mm plated holes. We can work with various substrates from standard rigid FR-4 to flexible PTFE, Polyimide, and PEEK materials.

We produce our own negatives for 0.3/0.3mm track and gap and PCBs can be turned around by the following day.

We also make our own solder masks which are essential for small-footprint components and enable oven reflowing of all components in one go, for speed and efficiency of assembly.

Our focused Infra-red rework system enables high-precision placement of Ball Grid Array devices.

Examples of some of the equipment available are:

LPKF Protolaser U3 Laser etching machine.

Multilayer press.

Spray etching and plating tanks.

PCB CNC machines.

Lynx VS8 PCB inspection microscope.

Automatic Pick and Place assembly machine

The mechatronics workshop specialises in small scale high precision work, fabricating rigs, jigs, and enclosures for applications in a wide range of disciplines like medical, RF, radar, and nanotechnology. The workshop can work with a wide range of materials from plastics, to metals with a wide range of specialist equipment for cutting, turning, milling, welding and 3d printing.

Examples of some of the equipment available are:

HP Jet Fusion 580 colour 3D printer.

Epilog legend EXT laser cutter.

XYZ 4 Axis mini mill 560 HD.

XYZ SLX 1630 CNC Lathe.

EMCOTURN E25 CNC Lathe.

XYZ SMX 2000 Turret mill, 3 axis CNC milling machine.

The workshop offers a full design and manufacturing service.

Please submit enquiries to workshop-jobs@ee.ucl.ac.uk or pcb-jobs@ee.ucl.ac.uk

Close

Close